Tried, tested, and still ahead of the curve

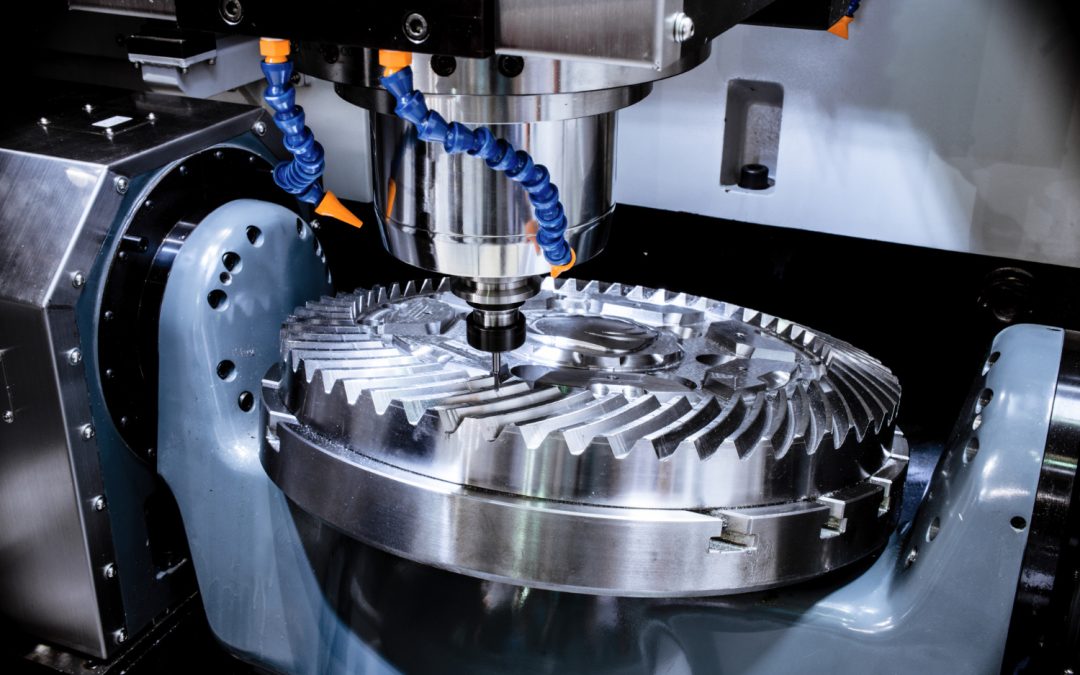

Technology in manufacturing keeps evolving, and while 3D printing and other fancy-sounding processes grab headlines, CNC machining has quietly stayed king in the product development world. Why? Because it just works—every time. CNC (Computer Numerical Control) machining combines digital precision with the kind of repeatability, speed, and material flexibility that newer methods are still trying to catch up with.

Whether you’re prototyping a new part, refining a product design, or getting ready for full-scale production, CNC machining still delivers results that are clean, accurate, and scalable. It’s a behind-the-scenes powerhouse that lets engineers and designers bring their ideas to life—without compromising on quality or turnaround time.

Precision that moves fast

One of the biggest advantages of CNC machining is its ability to handle tight tolerances with ease. This matters in industries where precision isn’t just a luxury—it’s non-negotiable. We’re talking automotive, aerospace, medical devices, and high-end consumer goods. If your part needs to fit perfectly, function smoothly, and look professional, CNC is the tool you want on your side.

And it’s not just accurate—it’s fast. Once the program is written and your design is locked in, CNC machines can run parts quickly and consistently. This is a major win for rapid prototyping and low-volume production where every hour (and every dollar) counts. It also means your design team can iterate faster, test components in real time, and move to production with confidence.

Material versatility meets design freedom

Another reason CNC machining remains essential is its ability to work with a huge variety of materials—plastics, metals, composites, you name it. While some production techniques are limited by material compatibility or require complex post-processing, CNC machines can jump between aluminum and ABS like it’s no big deal. That kind of flexibility means you’re free to experiment, test, and evolve your designs without switching tools or suppliers.

Plus, CNC machining plays well with other fabrication techniques. At The Pro Design Group, it often serves as the starting point for tooling, trimming, or laminating in more complex builds. Whether you’re creating a standalone prototype or a master mold for vacuum forming, CNC helps streamline the path from concept to reality.

Want to see how CNC machining supports full product builds? Check out our CNC Tooling & Design capabilities. Curious how it fits into broader production workflows? Explore our Custom Fabrication services. If you’re building products that need precise form and function, Vacuum Forming might be the next step. Ready to talk timelines or technical needs? Head over to our Contact Us page and let’s kick off your next CNC-powered project.