Blog

Vacuum Forming Materials 101: Choosing the Right Plastic for Your Project

Selecting the right material is one of the most important decisions in any vacuum forming project. The plastic you choose directly impacts durability, flexibility, appearance, and overall performance. Whether you are developing a prototype or preparing for full...

Lamination for Panels: When You Need a Clean Room, Tight Tolerances, and Long-Term Durability

Panel lamination is often the step that separates a product that looks “good enough” from one that performs reliably in the field. A laminated panel can improve appearance, stiffness, chemical resistance, and wear life, but only when the process is controlled. If...

The Ultimate Guide to Vacuum Forming: Uses, Benefits, and Best Practices

What Is Vacuum Forming? Vacuum forming is a streamlined thermoforming process where heated plastic sheets are shaped over a mold using vacuum pressure. As the plastic cools, it retains the mold’s shape, creating durable, lightweight parts with consistent detail. This...

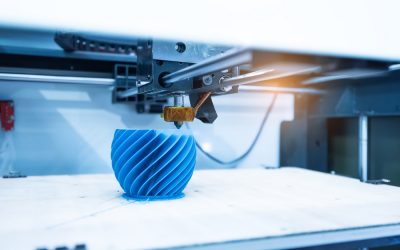

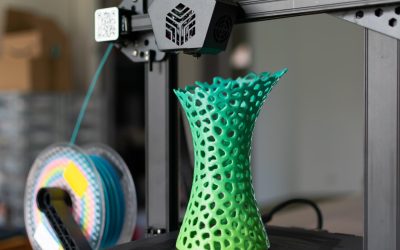

3D Printing: How It Works?

What Is 3D Printing, Really? 3D printing isn’t just for tech labs and hobbyists anymore—it’s shaping the future of modern manufacturing. At its core, 3D printing is an additive process where parts are built layer by layer from a digital file. But while that sounds...

What Is Thermoforming and Why It’s Still a Game-Changer for Custom Manufacturing

A decades-old process that’s still shaping the future—literally. If you've ever wondered how custom plastic parts are made quickly and affordably without sacrificing quality, chances are thermoforming had something to do with it. While it may not be the flashiest...

Elevating Surfaces: Why Professional Lamination Matters More Than Ever

In today’s competitive industries, surface durability and aesthetics are no longer optional—they’re expected. At The Pro Design Group, we specialize in transforming everyday materials into high-performance surfaces through advanced lamination techniques. With decades...

The Pro Design Group: Innovation, Craftsmanship, and Experience You Can Trust

Decades of Expertise in Thermoforming and Fabrication The Pro Design Group has been a trusted leader in thermoforming and fabrication since 1990. Founded by Chris Raab—who brought over twenty years of hands-on experience in the thermoforming industry—the company was...

Shaping the Future of Thermoforming and Fabrication

Innovation Born from Experience At The Pro Design Group, innovation isn’t just a buzzword—it’s the foundation of everything we do. Founded by Chris Raab in 1990, our company was built on more than two decades of experience in the thermoforming industry. This wealth of...

How Fast Can You Really Go with 3D Printing?

When you're sitting on a great idea, the last thing you want is to get bogged down in a six-month prototyping process. And in today's hyper-competitive product market, speed isn't just a perk—it's a necessity. That’s where 3D printing really shines. It’s not just...

Why CNC Machining Still Reigns in Modern Product Development

Tried, tested, and still ahead of the curve Technology in manufacturing keeps evolving, and while 3D printing and other fancy-sounding processes grab headlines, CNC machining has quietly stayed king in the product development world. Why? Because it just works—every...

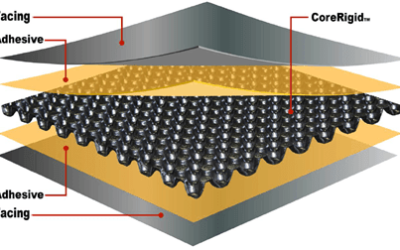

Why More Builders Are Switching to CoreRigid Panels for Their Projects

The Smarter Material Choice for Modern Builds If you work in construction, fabrication, or even transportation, you already know that traditional building materials like plywood and MDF often come with compromises. They’re heavy, vulnerable to moisture, and—let’s be...

What Exactly Is Thermoforming? A Simple Guide for Designers, Makers, and Curious Problem-Solvers

Understanding Thermoforming at Its Core Thermoforming is a manufacturing process where a flat sheet of plastic is heated until it becomes pliable, then shaped over a mold and trimmed into a final usable product. Once cooled, the material retains its shape with...