The ProDesign Group, located in Gardena, CA, stands as a pioneering force in precision machining, particularly in the realm of 5 axis CNC machine. Five-axis machining is a cutting method that is used to make high-quality parts. These cutting-edge machines have transformed the landscape of manufacturing, enabling the production of high-quality parts with unparalleled precision through the utilization of computer numerical control (CNC) technology. Previously this type of machining was only used for high budget manufacturers. However, technology has come a long way and is now more commonly available.

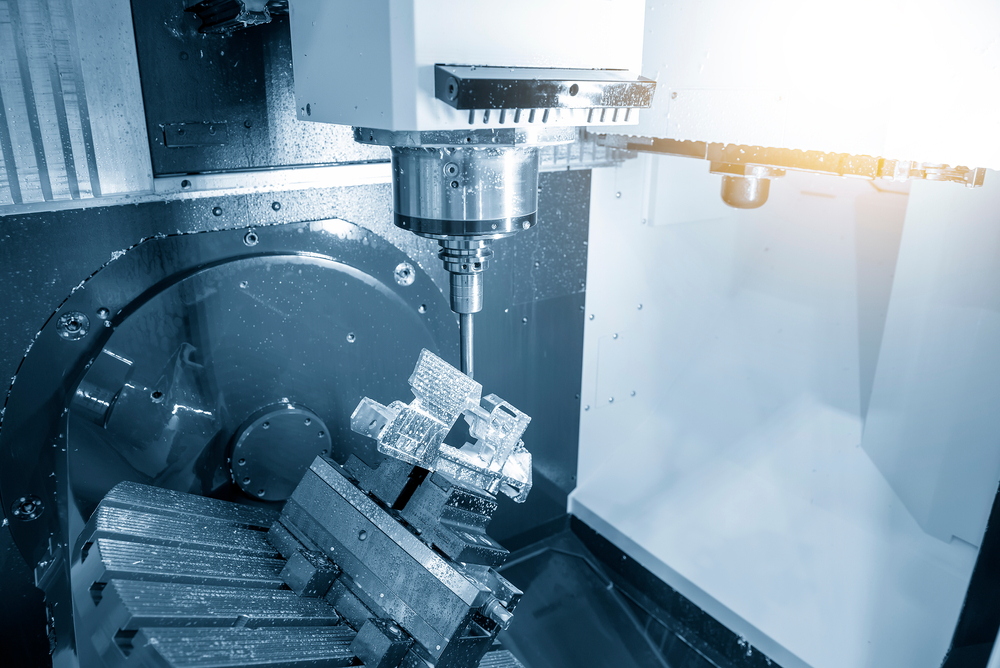

The 5-axis machines and mills are used in many aerospace applications and can cut intricate patterns. Additionally, they offer efficiency improvements for many products that might only require 3-axis machining. These machines work just like sculpting. You will take a large block of material and then remove the excess using a cutting tool. Pieces are slowly removed until the end object remains. The process is subtractive as opposed to something like 3-D printing, which is additive.

Most CNC machines will operate using an X, Y, and Z-axis. In 5-axis machines there are these three, but two of them will rotate, adding in an A and a B axis. This will allow the machine to make simultaneous movements to make designs that are smoother and more intricate. The added complexity of the machine will require computer-aided design and computer-aided manufacturing software that offers 5 axis capabilities.

The ProDesign Group’s commitment to staying at the forefront of technological advancements cements its position as an industry leader, harnessing the capabilities of 5-axis CNC machines to deliver precision and efficiency in the fabrication of intricate components. As technology continues its relentless progress, the widespread adoption of 5-axis machining is poised to redefine the modern manufacturing landscape, with The ProDesign Group leading the charge.