The process of designing a product mold can be complex and time-consuming, but there are details and elements that can be overlooked throughout the process. This is one of the reasons why it’s so beneficial to get to know a preferred molder early on in the design process.

Because choosing a molder can be set aside until completion of a product mold design and quoting by the purchasing department, this is why it can be challenging to establish this partnership so early. The process of designing a product mold requires the designer to understand the art of its design parameters with injection molding, so here’s the process of designing a product mold, and ensuring it follows the right protocol for your work as well.

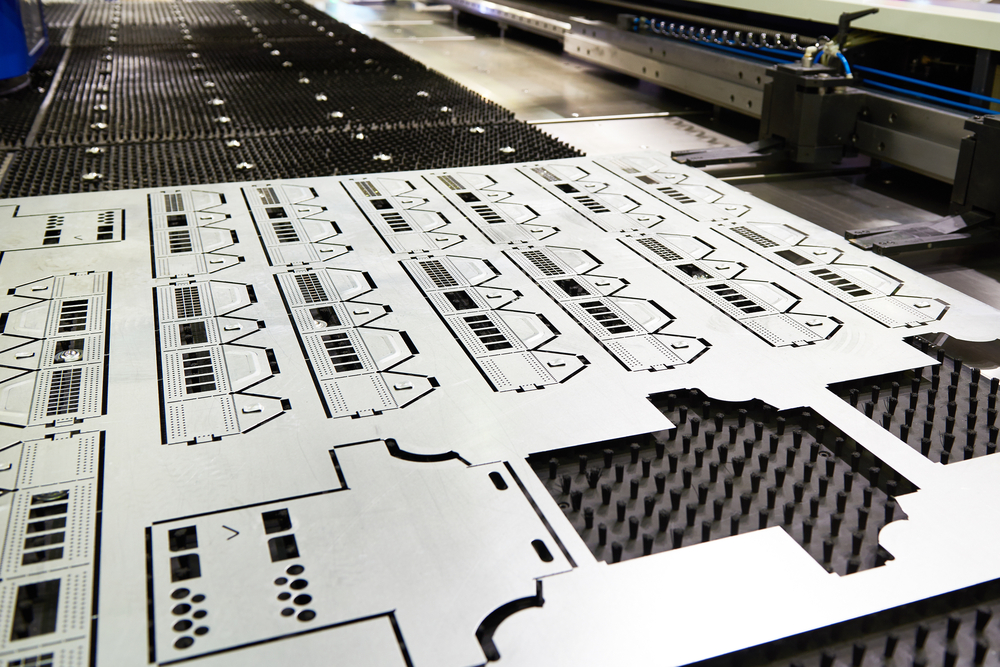

Review the basic type of mold to build. This can include the surface area, estimated weight, cavitation, daylight requirements, and mold construction. Parting lines will be the next point to consider for other partial aspects, including shape, quantity, parting sequence, and method, as well as location. Once it’s figured out how the part will be oriented within the mold itself, ask how the plastic will get into the mold. Items to consider include whether it’s a hot or cold runner, the gate location and sprue in relation to the part geometry, as well as runner size, shape, and balance.

Make sure location and adequate airflow are in place to help get rid of air throughout the mold and verify that methods for cooling are established as well. Airflow can impact the comfortability of a room, while also acting as a measurement for how the AC unit is performing. When you start to notice that there may be issues with the heating and cooling, these can be major factors to plastic molds for your project or home. When the mold’s plastic has significantly cooled down, the next thing to consider is removing the part from the mold.

Close the process to start the mold over again and make sure to understand methods to handle component change-outs.